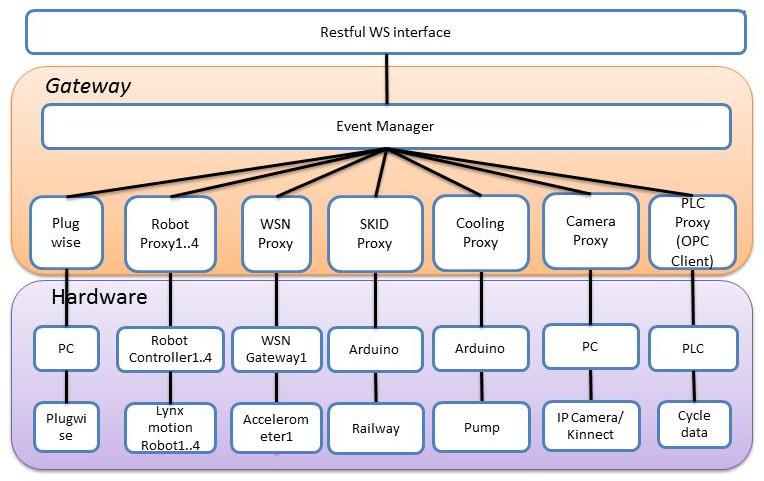

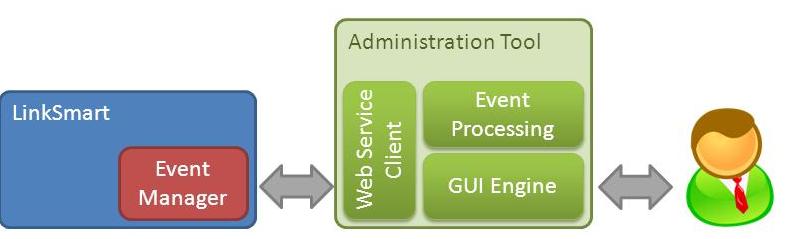

The main components in this prototype are described in Figure 1 below. The hardware level contains the drivers for the integrated hardware devices. At the gateway level we find the LinkSmart components such as the Event Manager and also newly developed LinkSmart proxies which interact with the different hardware drivers.

The LinkSmart proxies make the devices known in the LinkSmart network and provide services that can be invoked from different applications. Furthermore LinkSmart provides basic communication in the prototype such as service discovery and eventing. The eventing of LinkSmart is a simple publish/subscribe model that is based on topics. More information regarding LinkSmart can be found on the HYDRA project's website(LINKSMART, 2012) as well as here (LINKSMART, 2012).

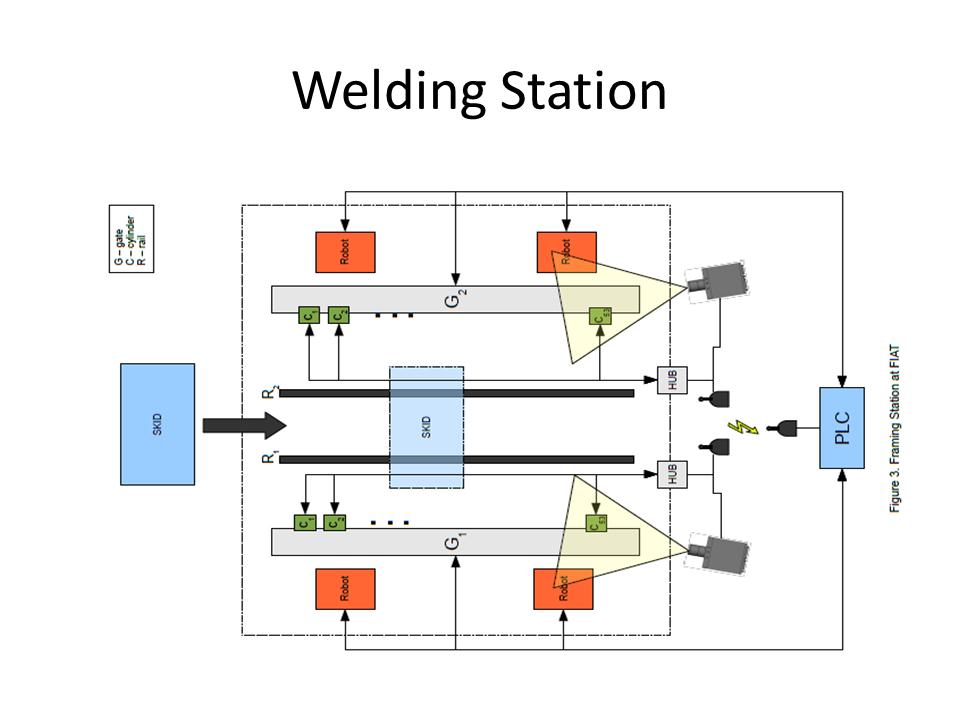

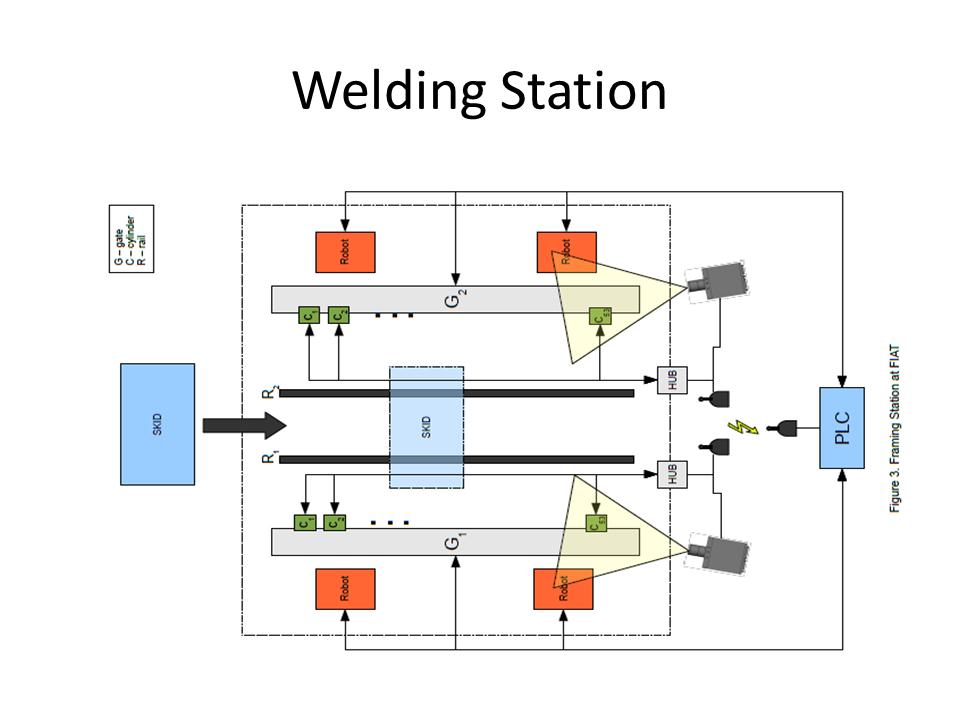

In order to test these components they have been deployed in the month 12 demo. The M12 demo is based on the scenario in Figure 2.

The scenario involves a welding station where car body parts arrive on a skid to be welded. This welding station contains a number of different devices:

• SKID : structure that carries the car body;

• SKID : structure that carries the car body;

• Rail: The SKID moves under two rails that have a specific code for positioning. This code is read while the SKID is sliding inside the Cell;

• Rail: The SKID moves under two rails that have a specific code for positioning. This code is read while the SKID is sliding inside the Cell;

• Gate: Devices locking the SKID with the car body after it is correctly positioned into the Cell. There are two of them to lock the two lateral parts of the car body;

• Gate: Devices locking the SKID with the car body after it is correctly positioned into the Cell. There are two of them to lock the two lateral parts of the car body;

• Cylinder: A cylinder is a component of a clip. The clips are responsible for locking the car body before the robots start the welding operation. Each cylinder has two sensors, indicating the status of that cylinder. For example, a cylinder has a sensor indicating an open state and a sensor indicating a closed state. There are 53 cylinders for each gate, or equivalently, 106 sensors;

• Cylinder: A cylinder is a component of a clip. The clips are responsible for locking the car body before the robots start the welding operation. Each cylinder has two sensors, indicating the status of that cylinder. For example, a cylinder has a sensor indicating an open state and a sensor indicating a closed state. There are 53 cylinders for each gate, or equivalently, 106 sensors;

• Robot: The robots doing the actual welding;

• Robot: The robots doing the actual welding;

• Hub: The state of each sensor is linked through a wire to a hub composed of 8 devices with 16 inputs. The state of each sensor can be transmitted to a PLC through a wireless link;

• Hub: The state of each sensor is linked through a wire to a hub composed of 8 devices with 16 inputs. The state of each sensor can be transmitted to a PLC through a wireless link;

• PLC: Device that commands all the operations in the cell, regarding, for example the gates, the movement of SKID and the clips.

• PLC: Device that commands all the operations in the cell, regarding, for example the gates, the movement of SKID and the clips.

Simulation

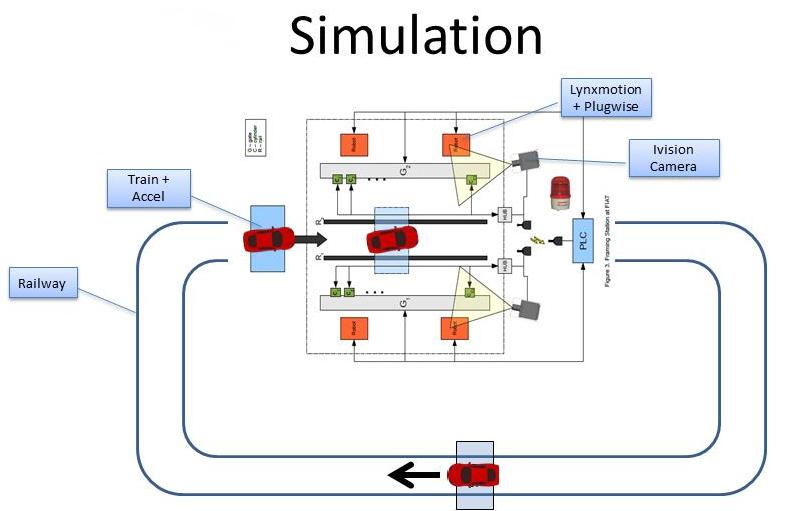

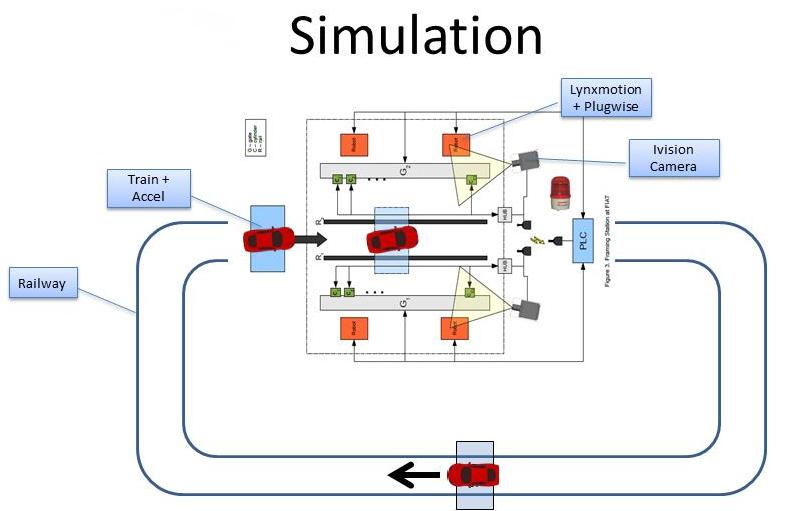

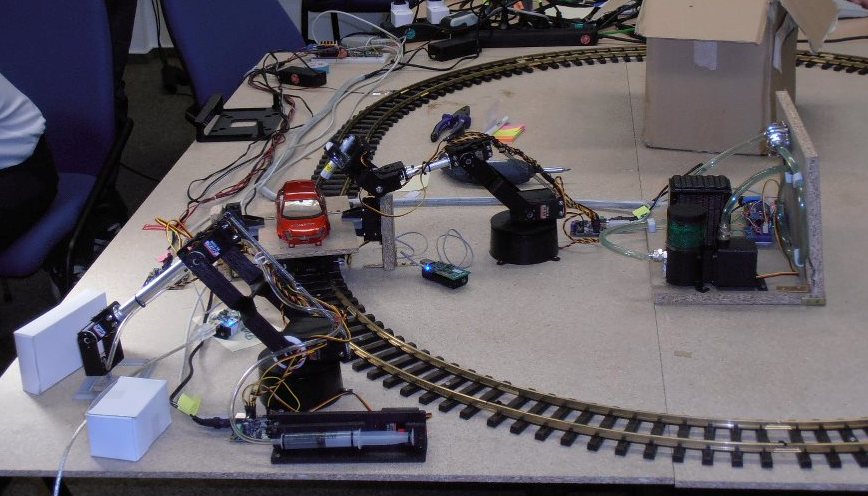

The actual M12 demo is a simulation of a subset of the welding station scenario with some devices simulated, see Figure 3.

The SKID is simulated by a train that can be controlled through software. The robots are not actual welding robots but are controllable “hobby” robots. The PLC and the vision system are not simulated but are the same as in the scenario.

The M12 demo uses the following steps:

• PLC runs a simplified framing station cycle

• PLC runs a simplified framing station cycle

o PLC waits until a car is in the station

o PLC waits until a car is in the station

• A car is entering the framing station

• A car is entering the framing station

o Use magnetic sensor to identify a car is in the station

o Use magnetic sensor to identify a car is in the station

• Stop the SKID (train)

• Stop the SKID (train)

o PLC cycle progresses & waits for position sensors to confirm

o PLC cycle progresses & waits for position sensors to confirm

• Sensor checks the position of the body

• Sensor checks the position of the body

o If the position is ok, publish ”event_frame_pos_ok“,

o If the position is ok, publish ”event_frame_pos_ok“,

Set variable in OPC, PLC runs the cycle further (step progresses)

Set variable in OPC, PLC runs the cycle further (step progresses)

PLC proxy publish “event_start_welding_event” (or the steps)

PLC proxy publish “event_start_welding_event” (or the steps)

o If the position is not ok, publish ”event_frame_pos_error“,

o If the position is not ok, publish ”event_frame_pos_error“,

variable in OPC, PLC runs the cycle further

variable in OPC, PLC runs the cycle further

• Pneumatic gripper(s) lock the SKID

• Pneumatic gripper(s) lock the SKID

o Set variable in OPC, Step cycle progresses

o Set variable in OPC, Step cycle progresses

• Lynxmotion robots wait for „event_start_welding_event”

• Lynxmotion robots wait for „event_start_welding_event”

o Robots move for a couple of seconds simulating a welding process

o Robots move for a couple of seconds simulating a welding process

o Show energy consumption of the robots

o Show energy consumption of the robots

• Robots finish the welding process

• Robots finish the welding process

o Robot proxies raise an event “event_finished_welding_event” and PLC Proxy set variable in OPC

o Robot proxies raise an event “event_finished_welding_event” and PLC Proxy set variable in OPC

• Pneumatic gripper(s) Unlock the SKID

• Pneumatic gripper(s) Unlock the SKID

• Run the SKID (train) forward until it gets back into the station again.

• Run the SKID (train) forward until it gets back into the station again.

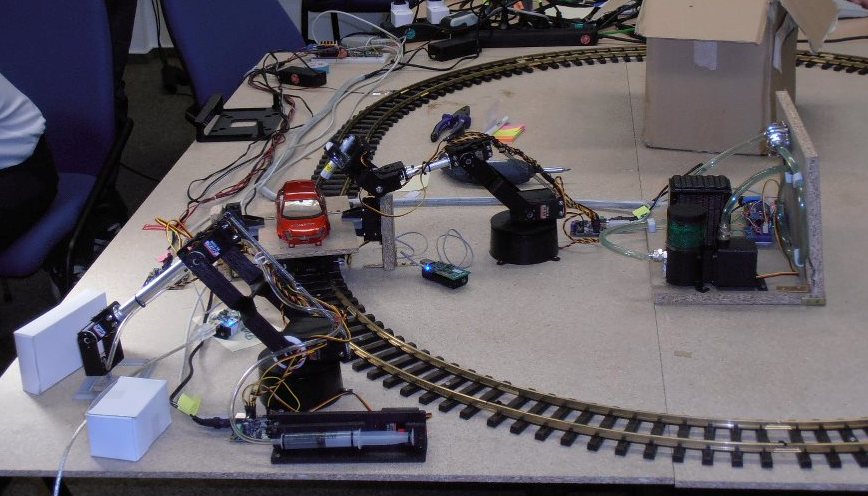

The picture below shows the actual setup of demonstrator during the review showing the robots, skid with car, vision system with mounted lamp and if one looks carefully one of the wireless sensors is visible just by the right robot.

At the M12 review the prototype was demonstrated with good results showing the different components working together but also showing that partners located in very different parts of the world can cooperate in creating the demonstrator.

to

the top